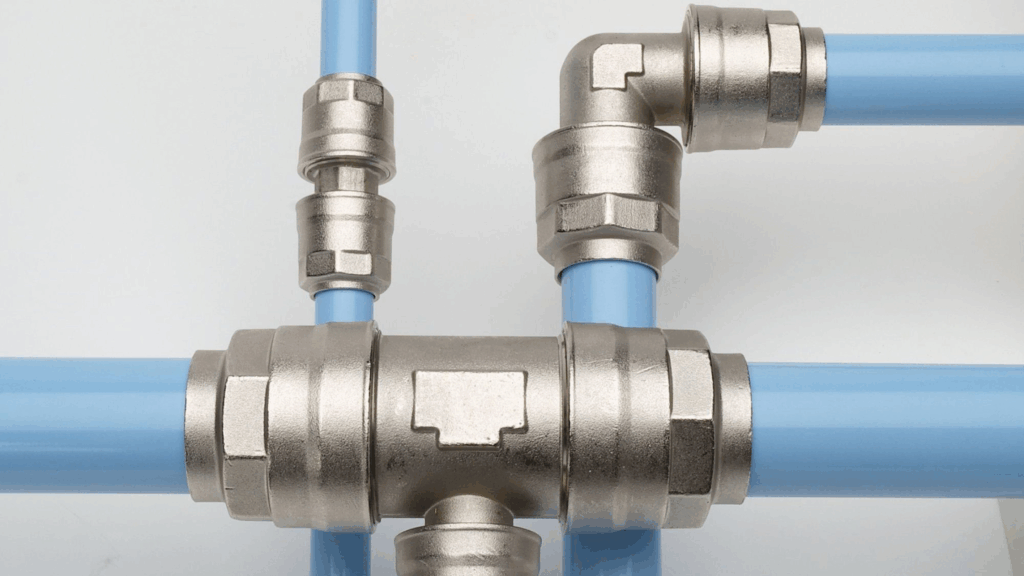

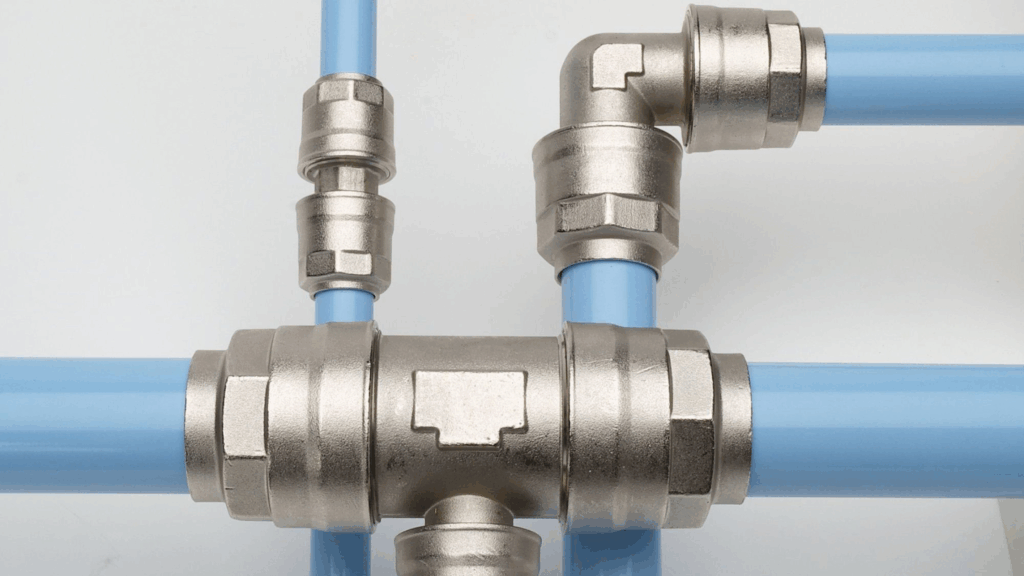

To understand the importance of couplings for compressed air, we must think of the number of industrial and handcraft scenarios which use technologies based on compressed air. In these scenarios, these couplings are connective elements that allow the passage of air through tubes, valves, cylinders and other devices of the circuit.

In this article we will analyse the various usage contexts.

Why couplings for compressed air are used

Couplings for compressed air are not limited to connecting: they must guarantee hold, resist pressure, prevent leakage and last over time even in the most hostile environments or with frequent use. The wrong choice can cause inefficiencies, system stops and elevated maintenance costs. This is why it’s fundamental to consider the type of application, pressure, capacity and compatibility with the materials involved in the various contexts.

Industrial systems and automation

In modern industrial systems, automation allows an increase in efficiency, reduction of errors and improvement in overall quality. In these scenarios, pneumatic systems powered by compressed air enable the function of automatic machinery, robots and packaging lines. The couplings for compressed air, therefore, become key components: they ensure the continual flow of air and the hold of the system throughout every phase of the process.

We also think about highly cyclical applications used in industrial robotics or in packaging, in which the speed and precision of the movement depend heavily on the dependability of the couplings and pneumatic connection: a leak or fall in pressure can compromise the entire production chain, causing machine stoppage and waste.

Also read “Hydraulic couplings: questions and answers”

Machine workshops and maintenance

Couplings for compressed air are the basis of many tools used every day in mechanic workshops: from compressors to air guns, even to pneumatic tools used for fastening, cleaning and maintenance operations, the functionality of the entire system depends on the quality and dependability of the installed couplings.

Here, too, couplings guarantee secure and leak-free connections, facilitating the rapid grafting or uncoupling of the tools. The quality of the couplings translates, therefore, into the possibility to work at full efficiency, avoiding falls in pressure or unplanned stops of operation.

In addition, in cases where flexibility is essential – as in mobile or modular workstations – rapid couplings allow connection and disconnection of tools in a practical and fast way.

Automotive and pneumatic sector

The automotive sector is a perfect example of how couplings for compressed air are essential in ensuring connections resistant to intensive cycles and pressure variations.

During assembly on an assembly line, pneumatic systems are used to power automatic tools for screw fastening, handling and component fastening, guaranteeing speed and efficiency.

Another critical area is that of pressure tests, where compressed air is used to test the hold of systems and circuits, like the brakes or air conditioning. In this application, the precision of the couplings is the determining factor in preventing leaks and obtain trustworthy data.

Also read “Metallic parts: prospects for the future”

Certified quality and customised components

Beyond the sectors listed above are building construction, the food, aerospace and med-tech sectors: in each application, couplings are one of the fundamental elements for guaranteeing efficiency, security and dependability of pneumatic systems.

Our work is to give our clients the security that comes from components of certified quality, designed and made to measure based on the specific needs of each system.

This is how it is possible to obtain optimal performance, reduce machine stoppages and ensure the maximum life of systems.