Precision milling has a central role in the production of milled components with reduced tolerances, treated surfaces and complex shapes, and, therefore, finds application in all sectors that require heightened performance and maximum dependability. Among these is the production of home appliances.

In this article, we will provide some indications for companies in the sector.

Precision milling in the production of home appliances

Precision milling is a branch of specialized mechanics. Different from traditional milling, this type of process is not limited to the production of standardized pieces, but allows the production of extremely accurate and repeatable pieces: elements such as shafts, bushings, screws, connectors or small metal items that are also used in the production of home appliances.

In a competitive market like this, the quality and dependability of the milled components translates directly into robust, efficient and valued final products. And the quality standards depend, primarily, on the capacity to work the materials and the level of precision.

Also read “The state of the art of CNC machining”

Most commonly used materials and their characteristics

This regards manufacturing, therefore materials, which are crucial to ensuring performance, durability and reliability. Among the most used are steels, aluminium and brass alloys, each with specific characteristics that define their applications.

Steels – particularly stainless steels – offer higher mechanical resistance, optimal workability and protection against corrosion. They are used in structural parts and components subject to stress or contact with water and heat, such as motor drive shafts, supports and screws.

Aluminium alloys are ideal when there is a need to reduce weight without compromising robustness: typical in movement mechanisms or in the internal components of small household appliances.

Brass, appreciated for its ductility and resistance to wear, is used on connectors, bushings and aesthetic parts, where a high level of surface finishing is required.

For household appliance producers, the choice of the correct material in the design phase is one of the elements that directly influences performance, costs and the operative life of the product.

Tolerances and surface finishes

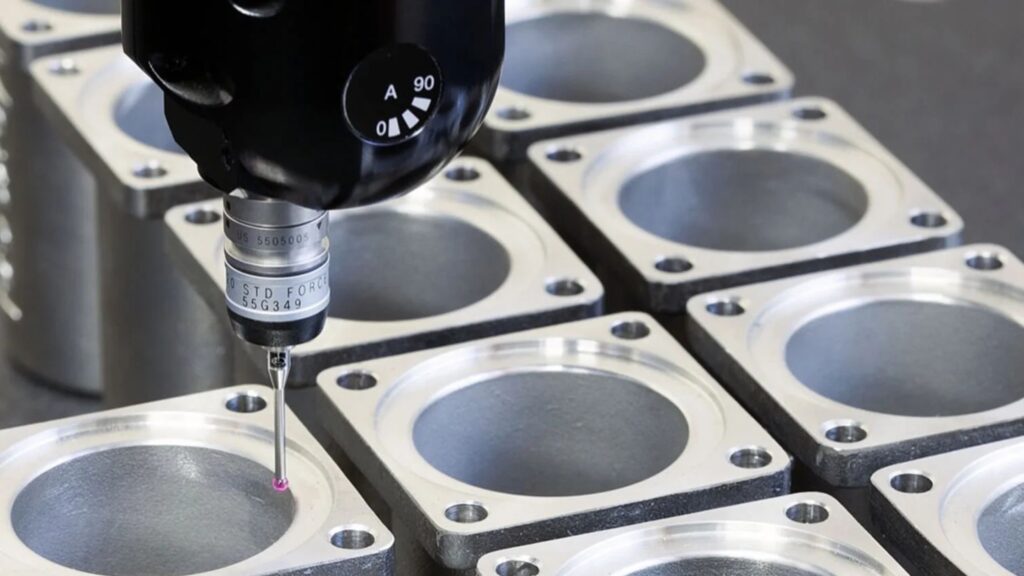

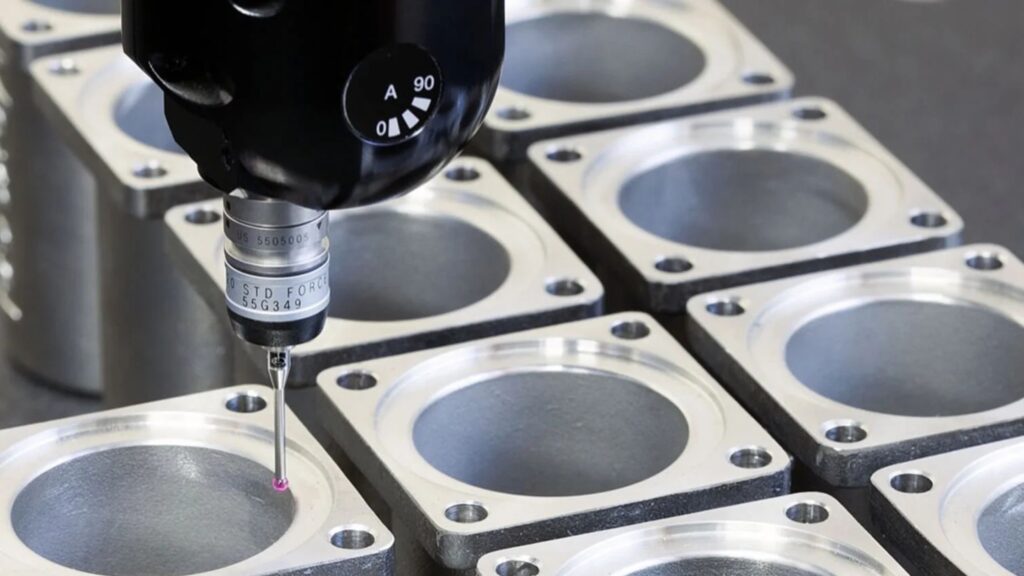

Each machined piece must respect strict size specifications: even a minimum deviation can compromise coupling between the parts, generate vibrations or reduce the life of the product. The size tolerances are defined in the design phase, in function of the use and type of material, and checked with high precision measurement instruments.

Surface finishing is equally important. Low roughness improves mechanical performance, reduces friction between moving components and limits wear. In sliding components, for example, a smooth surface ensures greater efficiency and less noise, qualities highly valued in small household appliances.

We also mention that the modern precision milling allows achievement of excellent aesthetic finishes already in the process, reducing the need for subsequent treatments.

Also read “Metal small parts: future perspectives”

Costs, times and production optimization

We have spoken about some of the main quality requirements for precision milling projects. Here are some of the steps we take to optimize production costs.

The management of costs, time and production optimization is a central aspect: each project must be planned according to the required quantities, the tolerances to be respected and the complexity of the piece.

For small series, flexibility and customization capabilities are a priority: we reduce set-up times and optimize the programming of CNC machines to guarantee speed and precision without excessive costs.

In the production of large series, we focus on efficiency. Here, process standardization, automation and continuous monitoring of production parameters allow us to reduce unit costs and ensure constant quality.

We also pay attention to machining waste: minimizing it means saving raw materials, time and reprocessing costs.

Finally, lead time: planning ahead and sharing previews of upcoming needs helps avoid bottlenecks and guarantees timely deliveries.