If we look at the area of machining for the automotive industry, in all of its various declinations, we see now over recent years it has undergone a significant evolution, guided by technological innovation and by the need to improve performance, safety and efficiency.

In this article, we will analyse this evolution and offer a panorama on the state of the art of precision hardware for the automotive industry.

Evolution of machining processes for the automotive industry

For years, the production of automotive components was mainly based on the use of traditional technologies, characterised by a greater level of manual work with a lower level of precision.

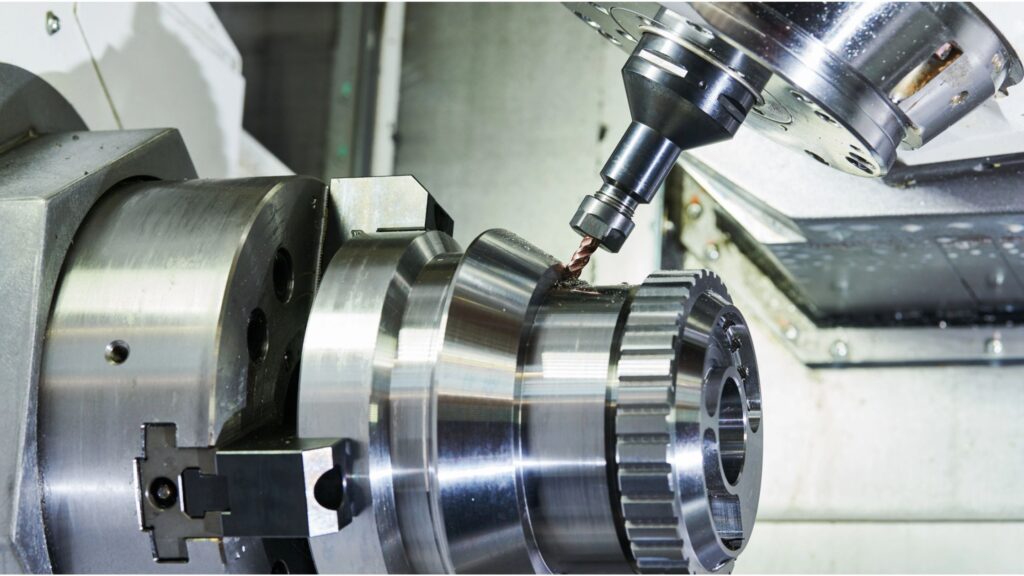

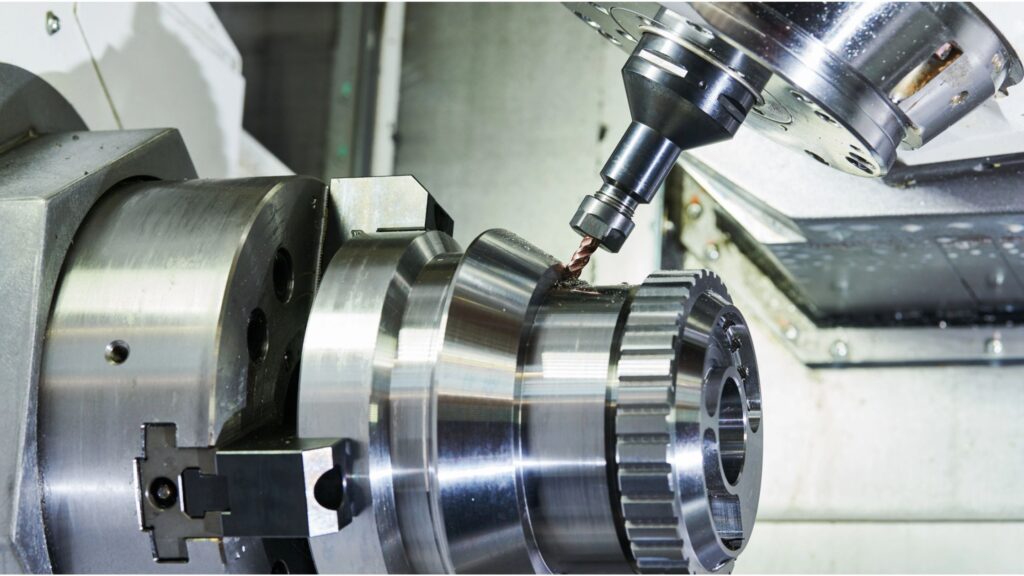

With the advent of CNC machines and industrial automation, production has reached levels of previously unthinkable precision and repeatability. The processes of turning and milling, once show and susceptible to human error, are now managed by digital systems able to guarantee minimal tolerances and high quality on a large scale. Contemporaneously, the use of new materials has transformed the sector.

Today, the production of components is more flexible, efficient and sustainable, quickly adapting to the needs of a market in continuous evolution.

Let’s see how and with which technologies.

Precision and quality: the role of CNC Machining

In the automotive industry – as in many other sectors – the performance of the products depends directly on the precision and quality of the components. CNC machining is instrumental in achieving these standards.

CNC machining is essential for the creation of cylindrical and axial components, guaranteeing perfectly finished surfaces and precise geometries. Milling, however, allows production of complex parts with accurate details, essential for high performance structural and mechanical components.

A key step for the final quality is grinding, which ensures extremely smooth surfaces and micrometric tolerances, indispensable for components subject to elevated levels of mechanical and thermal stress.

Automation and Industry 4.0 systems find their application in this context.

Automation and Industry 4.0 in automotive industry production

Without a doubt, of the technologies that have most greatly revolutionised machining processes for the automotive industry those linked to Industry 4.0: those used at our plant improve efficiency, quality and competitiveness.

This is also thanks to production digitalization, which allows us to constantly monitor the lines through the addition of IoT systems (Internet of Things), an approach that opens the door to a greater capacity to adapt to the variations of the request, guaranteeing quality standards.

AIn the light of the competitive advantages that it can guarantee, the implementation of Industry 4.0 systems in precision lathing is ever more necessary, positioning sector companies to face the challenges of an increasingly demanding and evolving automotive industry.

What to expect in the future

The integration of robotics, artificial intelligence (AI) and machine learning in today’s processes has the potential to significantly improve every phase of the production process, both in terms of quality and use of resources.

Collaborative robots (cobots) are increasingly used in production lines, supporting assembly, machining and quality control operations. Thanks to their precision and repeatability, they reduce the margin of error and increase productivity.

Artificial intelligence allows analysis of an enormous quantity of data in real time, optimising machining parameters and identifying potential breakdowns before they happen.

In effect, it is a predictive approach, able to reduce machine stops and improve maintenance management.